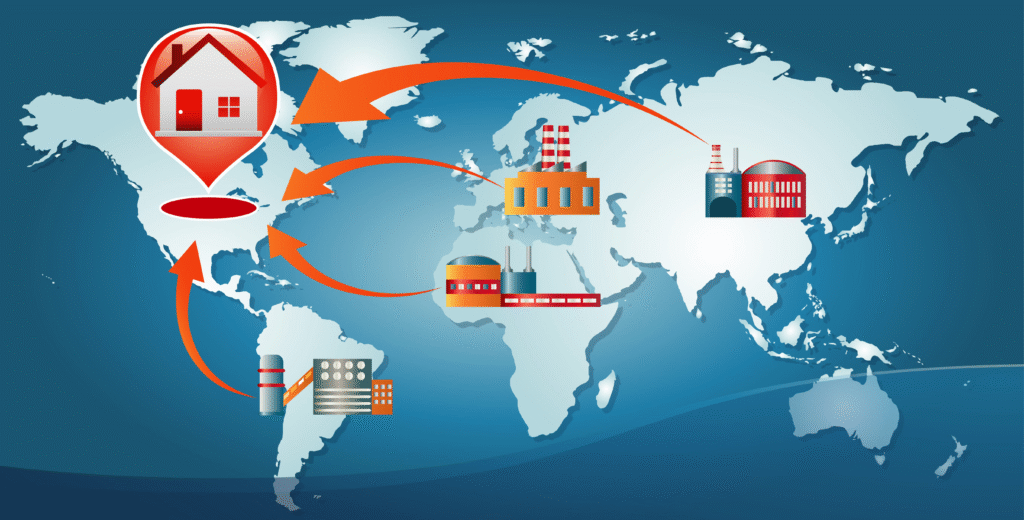

In the global economy, tech-forward companies are looking beyond traditional strategies to gain a competitive edge. One area receiving significant attention is supply chain management. Once viewed as a back-office function, the supply chain is now seen as a strategic driver of growth, efficiency, and resilience. Modern organizations are increasingly investing in digital tools to optimize their supply chains, and for good reason.

The Shift Toward Data-Driven Decision Making

Supply chains generate massive volumes of data, from inventory levels to supplier performance metrics. For years, much of this information went underutilized due to a lack of integration and visibility. Now, with advanced analytics and cloud-based platforms, companies can harness this data to drive smarter decisions.

By leveraging real-time data, tech-forward teams can forecast demand more accurately, avoid costly disruptions, and respond swiftly to market changes. Whether it’s identifying a potential bottleneck or re-routing shipments during unexpected delays, modern supply chain tools make proactive management possible.

The Push for Greater Transparency and Compliance

Increasing regulatory pressures and heightened consumer awareness have put a spotlight on supply chain transparency. Organizations are expected to monitor not just the quality of products, but also the ethical and environmental practices of their suppliers. Manual processes make this difficult, often leading to gaps in compliance.

Digital supply chain tools simplify the process of auditing suppliers, tracking certifications, and documenting sustainability efforts. This not only minimizes risk but also builds trust with stakeholders, from customers to investors, who demand greater accountability.

Enhanced Supplier Collaboration Through Technology

Strong supplier relationships are key to a resilient supply chain. Traditionally, these relationships have been managed through a mix of emails, spreadsheets, and meetings, hardly the most efficient or scalable approach. Today, companies are turning to digital platforms that centralize and streamline supplier interactions.

An srm software company can provide tools that allow for seamless collaboration, shared performance dashboards, and automated feedback loops. Doing so ensures suppliers stay aligned with company goals and helps foster long-term partnerships built on mutual success.

Cost Reduction Through Automation

Supply chain automation is transforming the way businesses manage logistics, procurement, and inventory. With tools that can automate everything from purchase orders to invoice matching, organizations can significantly reduce manual work and human error.

For example, automated demand planning tools can help ensure the right products are ordered at the right time, minimizing excess inventory and storage costs. Transportation management systems can optimize delivery routes and reduce fuel expenses. The result is a leaner, more cost-effective operation that improves profitability.

Building Resilience Against Disruption

The COVID-19 pandemic was a wake-up call for many businesses, revealing the vulnerabilities in global supply chains. Since then, companies have prioritized resilience alongside efficiency. Digital supply chain tools are essential in achieving this balance.

Scenario modeling, risk assessment dashboards, and multi-tier supplier visibility platforms enable organizations to prepare for disruptions before they occur. This level of preparedness is no longer optional; it’s a competitive necessity in an unpredictable world.

Future-Proofing Operations

Investing in supply chain technology is not just about solving today’s problems. It’s about future-proofing your business. As artificial intelligence, blockchain, and the Internet of Things (IoT) continue to evolve, supply chain tools will become even more intelligent and integrated.

Companies that lay the foundation now by adopting flexible, scalable tools will be better positioned to adapt to new technologies and market demands. They’ll also be more agile, able to pivot strategies without overhauling core systems.

Conclusion

Tech-forward teams understand that the supply chain is no longer a back-end function; it’s a strategic asset. By investing in digital tools that improve visibility, automate processes, and enhance collaboration, businesses can build supply chains that are not only more efficient but also more resilient and responsive.